Quality standards

CIPRIANI SRL

Reliability, precision and research are in our DNA

We strive every day to achieve our goals with enthusiasm and professionalism, offering our customers a top-notch machining process. Highly qualified staff, Technology 4.0 and an automated storage system for storing and managing materials.

Learn about the technologies and practices that have made Cipriani Srl a leader in SMT and PTH assembly.

For more information about our manufacturing processes, please leave your data and you will be contacted by our sales manager.

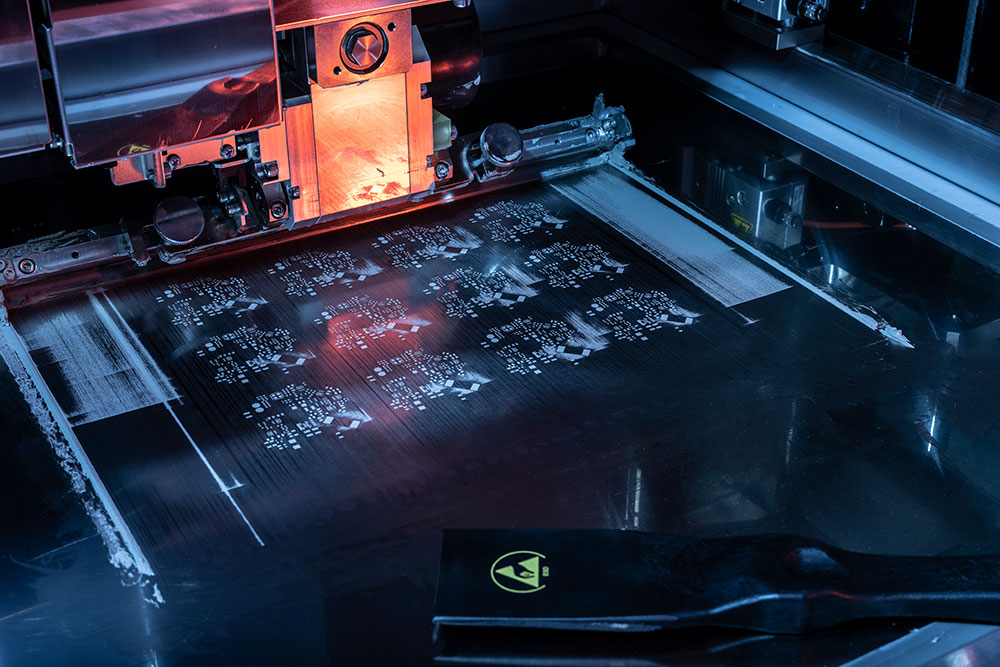

4.0 technologies

A remelting furnace for each processing line for faster and more accurate production and assembly machinery with fully automated work lines to drastically reduce operator handling.

At the end of each processing step, product validation occurs through automatic screen printing process control (SPI) andautomatic optical inspection (AOI 3D).

assembly lines

- 5 complete SMD LINES of S.P.I. and A.O.I. 3D

- 3 PB FREE wave welding lines

- 1 PB FREE Selective welding line

- 1 PTH insertion line Axial and Radial Universal 8

- 2 DEPANNELING Laser

- 3 DEPANNELING Router

Conformal coating

- Dedicated area

- 2 automatic lines for Conformal coating of boards

Testing

- 5 BENCHES SPEA 3030 Multimode Dual Bay

- 5 DESKS SPEA Unitest 500 ADP

Warehouse

The management and conservation of materials is very important for us. The flagship of Cipriani Srl is the warehouse with automatic storage system that allows us to monitor, categorize and sort materials avoiding so many risks that companies that use the old shelving system.

After the delicate incoming and control phases, each single component is catalogued and equipped with a unique code so as to allow its tracking at every stage of processing. All materials are stored in 14 warehouses automatic temperature-controlled, to preserve the integrity of each individual component.

- Conditional raw material warehouse

- X-ray system for counting components avoiding the unrolling of the coils

- Packaging Management and Repackaging of materials

- Coded materials for traceability and quantity monitoring

- Temperature and humidity controlled cabinet for storage of MSL components

ESD standards

To protect processing areas from electrostatic discharge and to preserve electrical components and equipment, we have equipped our plant with ESD-compliant floors, platforms and containers (in which processing materials are stored).

But not only the surfaces, even the uniforms worn by our operators comply with these directives.

The human body, in fact, has a high electrical conductivity and this means that even just walking in the work area or touching equipment and equipment generates static electricity, which is often not even perceived by the individual, but that risks damaging the components.

- Specific areas of the shed are designed to be protected from electrostatic discharges

- Containers for storing, transporting and protecting electronic components

- Operators' uniforms with ESD protection